Before aerial photography arrived most maps were highly inaccurate by modern standards.

Rubber sheet gis.

Features may move depending on their proximity to and length of displacement links.

New tutorial video on gis practical.

Sheet rubber rubber sheet rubber rolls rubber strips neoprene silicone viton epdm spec grade rubber manufacturer rubber products neoprene rubber.

According to your specifications.

Use displacement links to define common locations in the source and target layers.

Rubber sheeting is a useful technique in historical gis where it is used to digitize and add old maps as feature layers in a modern gis.

Geo referencing through rubber sheeting most suited for bhutanese students cnr.

In rubbersheeting adjustments you are usually trying to align one layer with another that is often in close proximity.

Rubbersheeting is typically used to align two or more layers.

Since our sheet rubber is sold in roll form they can be acquired in custom lengths of up to 25 or 50ft.

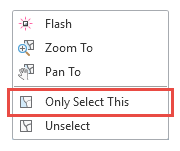

This exercise will show you how to rubber sheet data by using displacement links multiple displacement links and identity links.

Sheeting rubber products are most often sold in the form of rolls.

The input point features represent identity links that hold source positions unmoved during the rubbersheeting process.

The source layer drawn with solid lines is adjusted to the more accurate target layer.

Conveyor belts lacing.

Rubbersheeting is used to make small geometric adjustments in your data usually to align features with more accurate information.

Links representing from and to locations are used to define.

Rubbersheeting is used to make small geometric adjustments in your data usually to align features with more accurate information.

Rubber sheeting registration by relative position is the procedure using slave and master mathematical transformations to adjust coverage features in a nonuniform manner.

The input link features represent the regular links.

Our sheet rubber rolls are usually stocked in gauges between 1 32 to 2 in thickness depending on the specific type of elastomer.

This process moves the features of a layer using a piecewise transformation that preserves straight lines.

Random geometric errors are corrected through a process known as rubber sheeting.

Rubbersheeting makes spatial adjustments to align the input feature locations with more accurate target feature locations based on the specified rubbersheet links.